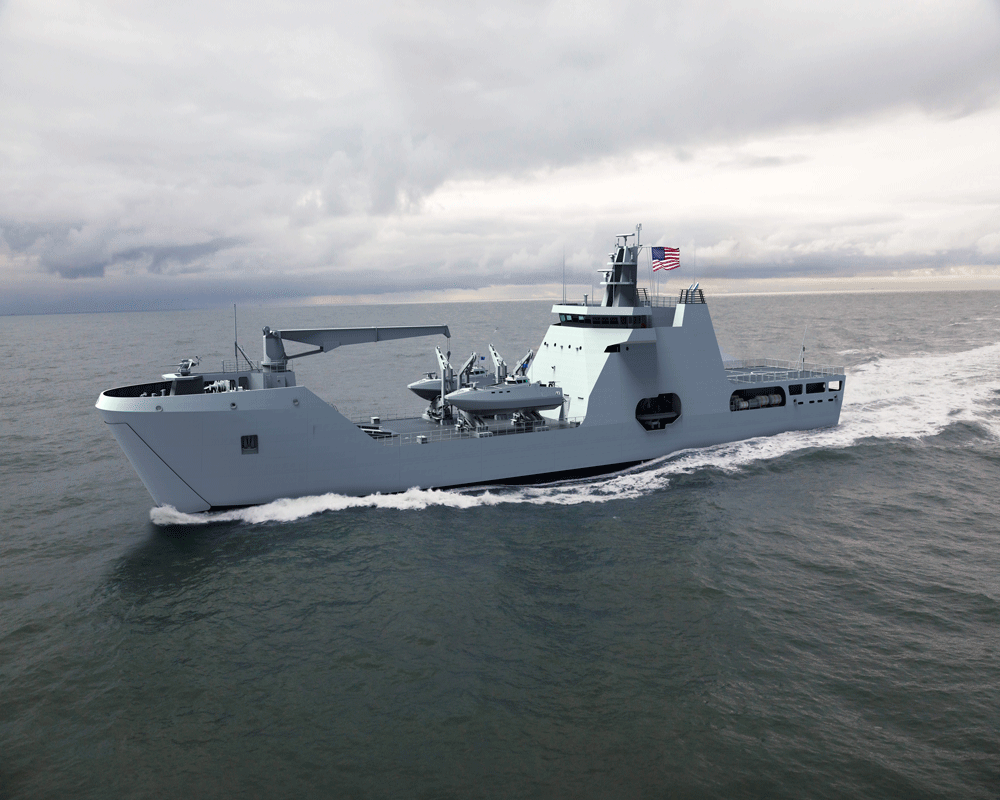

Ocean Breeze is the first of six China-built, dual-fuel LNG PCTCs scheduled for handover to Sallaum Lines by 2027

Ocean transportation company Sallaum Lines has shifted toward ordering LNG newbuilds, following initial reliance on second-hand vessels for its PCTC fleet, as part of an ambitious goal to achieve net-zero operational emissions by 2050.

“The decision to order newbuilds was driven by technical and environmental performance objectives, not by cost alone,” Charbel Khoueiry, maritime sustainability manager, says. “Sallaum Lines required vessels that could fully comply with IMO Tier III, the IGF Code, EEDI Phase 3 and forthcoming CII targets, while integrating dual-fuel LNG propulsion, electric vehicle-ready cargo decks and advanced hydrodynamic features.

“These parameters would have been impossible to achieve through retrofit without extensive structural and machinery compromises. Newbuilds designed from the keel up provide optimised hull efficiency, lower emissions and long-term lifecycle compliance with current and anticipated regulations.”

Consequently, Sallaum Lines is adding six large, dual-fuel LNG PCTC newbuilds to its fleet. The first duo in the series – the 199.9m, Ocean Breeze and Ocean Explorer – were designed by Shanghai Merchant Ship Design & Research Institute (SDARI) and constructed by Fujian Mawei Shipyard, with Ocean Breeze delivered in Q3 2025 and Ocean Explorer scheduled for delivery in Q1 2026. A further four PCTCs, designed by Deltamarin are currently under construction at China Merchants Heavy Industries (CMHI) and scheduled for delivery throughout 2026-2027.

Ocean Breeze runs on LNG, MGO and VLSFO, and can operate in LNG-only, fuel oil-only or dual-fuel modes, depending on prevailing voyage or port conditions. Khoueiry explains: “We selected LNG because it offers a proven, commercially available and technically mature, low-emission pathway that complies with current environmental regulations. It eliminates SOx and PM, reduces NOx by up to 80% through exhaust gas recirculation [EGR] and lowers CO2 by approximately 20–25%.”

At a continuous sailing speed of 17knots, the vessel is estimated to achieve a range of approximately 12,600nm when operating on LNG, 3,000nm on MGO and 7,800nm on VLSFO. Taken together, the vessel’s total potential sailing range with full tank capacity is approximately 23,400nm.

The powertrain aboard Ocean Breeze incorporates a MAN B&W main engine, rated 12,614kW at 99rpm, and three auxiliary Wärtsilä 9L20DF engines, rated 1,613kW apiece, in addition to a 200kW emergency generator. “All machinery is installed in an aft engine room with segregated LNG and ventilation spaces, in accordance with the IGF Code and ABS requirements,” says Khoueiry.

The ship is also fitted with two Type C LNG storage tanks, each featuring the capacity for about 1,768m3 of LNG.

LNG is vaporised and supplied to the engines via a dual-pressure fuel gas supply arrangement, providing high-pressure gas at approximately 315bar to the main engine and low-pressure gas to the dual-fuel generator engines.

The PCTC is equipped with a single fixed-pitch propeller and a semi-balanced twisted rudder with bulb, developed by SDARI to enhance propulsive efficiency. The vessel is designed for a service speed of 18.5knots at design draught, allowing for a 15% sea margin.

The ship was classed by ABS, achieving full IGF, ENVIRO and operational notations. “Safety features include gas-tight LNG spaces, independent ventilation, double-walled gas piping, ESD systems, CO₂ fire protection and EV fire zones with continuous detection for the hydrogen/CNG vehicle areas,” says Khoueiry. This was accompanied by crew training in LNG handling, carried out in line with IMO/IGF Code competence standards.

As another green bonus, the ship has been treated with Chugoku Marine Paints’ SEAFLO NEO SLZ low-friction antifouling coating, developed to keep the hull continuously smooth, reducing hydrodynamic drag and fuel consumption and enabling higher vessel speeds.