News Article

Sallaum Lines moves in on net-zero with newbuild PCTC Ocean Breeze

A series of six LNG-enabled pure car and truck carriers are set to play a crucial role in Sallaum Lines’ efforts to decarbonise its transportation operations

29th Jan 2026

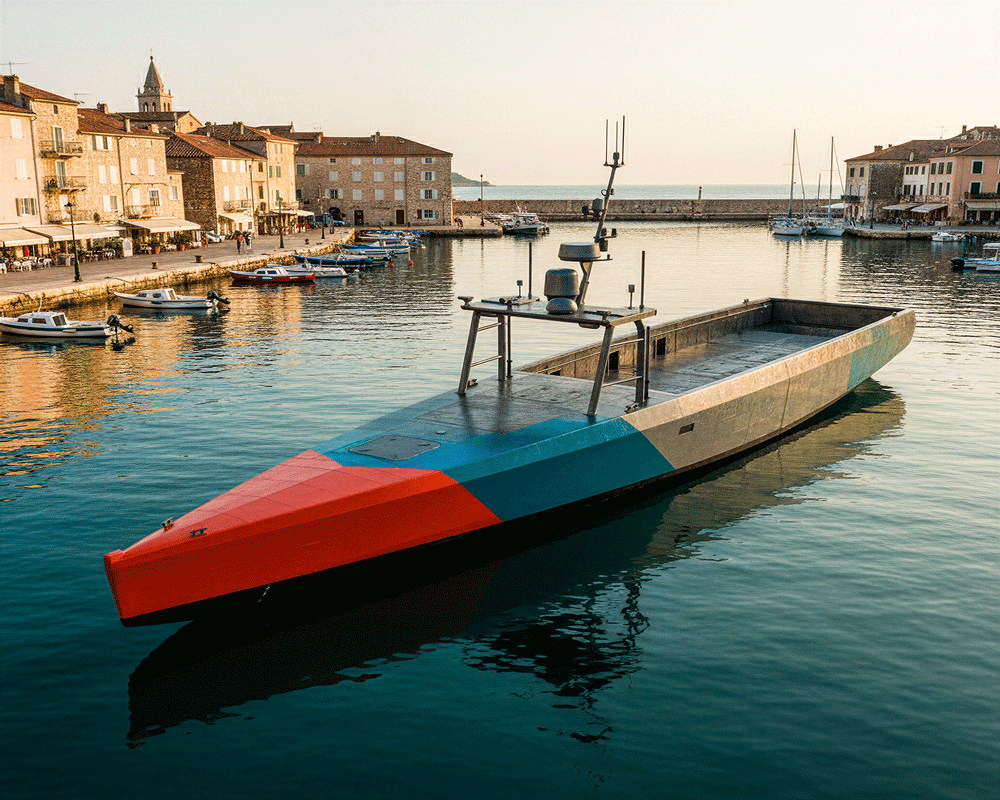

The Oceanus17's payload bay will measure 9m x 2.8m, with the capacity to accommodate a 20' container (image: Chris Blount)

Already under construction at Manor Marine, with a scheduled launch date of June 2026, the first Oceanus17 will “have a flavour of the military about it, but be very much a dual-role vessel,” Matthew Ratsey, founder and MD of ZeroUSV, says. “The feedback we’re getting from wind farm service operators is that they want to increasingly use remote-operated vehicles [ROVs], and the Oceanus17 can function as a ‘mothership’ to launch and recover ROVs, and as a ‘comms node’, tracking the ROVs’ positions when they are deployed – which has massive benefits in not losing a single ROV.”

Ratsey adds that ZeroUSV was recently approached by a company that manages the offshore facilities for several energy majors, with a view to using a fleet of USVs to deliver post and spares to these sites, as a cost-efficient alternative to expensive helicopter hire. This is a task the forthcoming Oceanus17 could easily handle given its aft deck payload capacity of 4tonnes, Ratsey points out.

Oceanus17 will comprise an all-aluminium, 16.97m x 3.17m monohull with the ability to maintain range for more than 50 days.

One of ZeroUSV’s goals was to “compress traditional defence acquisition timelines”, where the journey from design to prototype can roll on for years, Ratsey notes. So, for the Oceanus17, ZeroUSV chose to use a ‘spiral development process’, accelerating the design, engineering and build phase by basing the new model heavily on the Oceanus12 – essentially treating the existing USV as a ‘building block’ for the newer, bigger model.

Ratsey elaborates: “We’ve taken most of the core engineering we used for the Oceanus12 – what we know works and is reliable – and asked ourselves, what is the biggest vessel we can build with this engineering package? This includes the engines, the batteries, the battery chargers and the generators used in the Oceanus12 – we designed enough capacity into those components the first time around, we can reuse them in the Oceanus17.”

Another benefit of the spiral development process is that, by using the same components as the Oceanus12, end users can utilise the same spares packages with the newer model. USV familiarisation is another bonus. The biggest boon, though, from a USV manufacturer’s perspective, is perhaps the ability to speed up necessary certification. Ratsey explains: “The fact that we’re using 95% of the same equipment from the Oceanus12 on the Oceanus17 means that, when we come to enter the Maritime and Coastguard Agency [MCA] Workboat Code 3 process, all our current mitigations and submissions are transferrable – they just apply to a slightly larger version of the vessel.”

The Oceanus17’s payload bay will measure 9m x 2.8m, and will have the capacity to accommodate a 20’ container, with power and data connection points. The USV will also feature Starlink and Iridium connectivity and will incorporate an autonomous software package provided by ZeroUSV’s long-term partner Marine AI – rated to level 4 autonomy, but future-proofed for further upgrades. In addition to the boat’s primary sensors, customers will be able to select FLIR thermal IP cameras and W-band HD radar, among other options.

While Manor Marine puts the USV together, working with materials and components pre-issued by ZeroUSV, an independent contractor will oversee the boat’s electrical fit-out. If all goes to plan, the Oceanus17 will be launched in time for this year’s Seawork expo, to be hosted in Southampton, UK between 9-11 June. Then, in July, the boat will be certified by MECAL to meet the MCA Workboat Code 3, Annex II requirements for uncrewed vessels and unlimited operations.